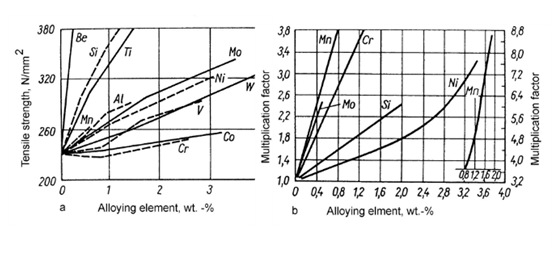

Powder metallurgy materials with traditional casting process can not be obtained the unique chemical composition and physical and mechanical properties such as porosity, controllable material, material microstructure and macro segregation (no alloy after solidification in different parts of the section without chemical composition caused by liquid alloy macro flow uneven), can be a molding etc.. For powder metallurgy parts, the main factor determining the mechanical properties is the density of sintered parts. Any factors that are beneficial to increase the density of sintered parts can improve the mechanical properties of the final product. The greater the density of sintered parts is, the higher the mechanical properties. However, as long as the density of sintered parts can not reach the theoretical density of the corresponding dense materials, the mechanical properties of sintered materials are lower than those of the corresponding dense materials. For example, steel should pay attention to carbon steel (iron-based sintered material made of iron and carbon) and sintered steel with alloying elements. Their strength increases with the increase of alloy element content, but toughness and impact energy value decrease. Therefore, the toughness and the impact energy value of the iron based powder metallurgical structure are reduced with the decrease of the material density and the increase of the content.

In the production of powder metallurgy structural parts, compound pressure and two times sintering are often used to improve the material density of parts. The repressing is similar to finishing. The higher pressure is applied to increase the overall density of parts. The effect of cold working hardening can be eliminated by two times sintering. The two time sintering refers to the repeated sintering. Therefore, the strength and toughness of the material of the structural parts can be improved because of the high density of the material which has been repressed and two times sintered.